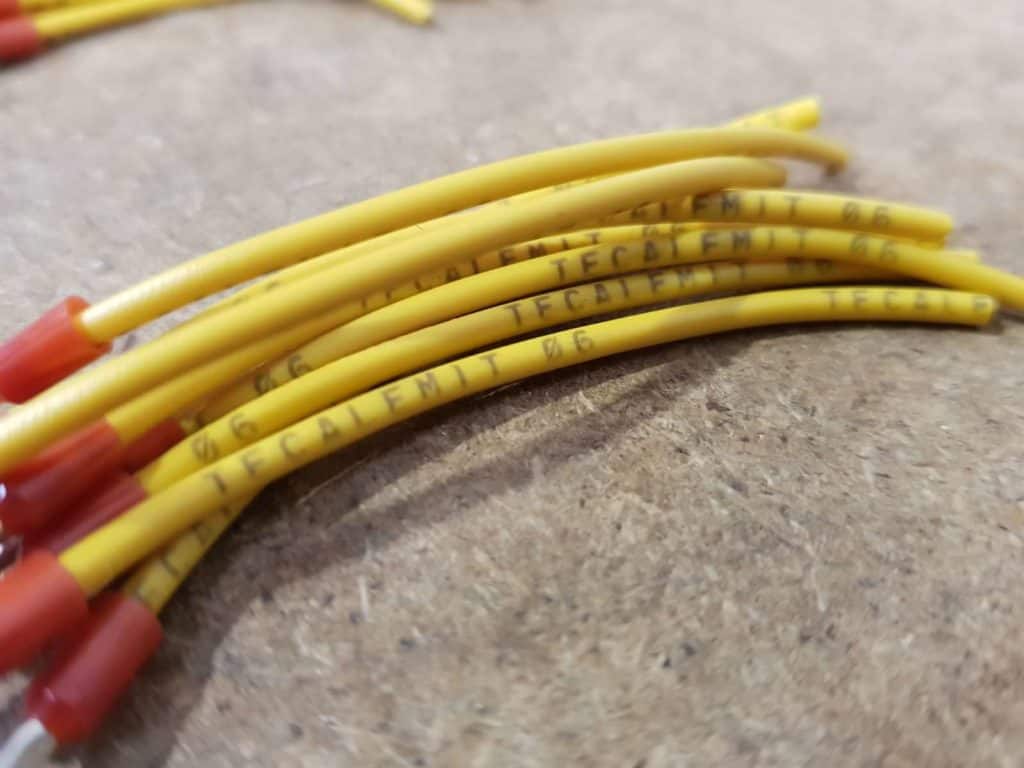

We have specialised fully automatic wire cut, strip and crimping machines which have the ability to produce 3000 wires an hour.

We have developed and put in place quality processes and we are able to rapidly produce custom cables for you in a very short time frame. Not only are our lead and development times are high, but our quality is always to the highest standards. Every cable produced by Lupson electronics undergoes an inspection process to ensure you always receive a perfect product. Whether you require 10 or 10,000 cables, we are able to meet your needs and produce consistent, high-quality custom cables in low and high volumes, within a practicable time frame. From an initial telephone conversation discussing your requirements, we are able to advise on whether we can be of assistance to your business.

Fully automatic machines

Quality products

Fast lead times

Attention to detail

We use the latest Stripping and cutting equipment as well as hydraulic pressure crimpers to ensure consistency and quality between custom cable assembly.

First, we like to obtain a sample from you or a drawing of what you require and then we recreate this for you so that you can clearly see the quality in the production and the supplies that we use. Then, we use computerised cable production equipment which has eliminated any faults experienced during the testing phase of our cable assembly and production process. Once we have assembled a computerised cut list, it is saved in our database ready to be applied to the cables production. We can easily recall this cut list and produce more cables as required. It is as simple as a phone call and cabling can be dispatched straight to you within days. Our modern facilities allow us to keep up to date with modern technological requirements and business needs.

We're specialist cable assembly manufacturers in the UK producing wire looms, wire harnesses and a wide range of other electronics too. Get in touch and enquire about our services and state of the art cable manufacturing facilities.